|

|

Product Overview

The WQ(D)-QG submersible sewage and sludge cutting pump (hereinafter referred to as the electric pump) consists of three parts: a pump, a seal, and a motor. The motor is located at the top of the electric pump and is a single-phase or three-phase asynchronous motor. The pump is located below the motor and has a semi-open spiral impeller and volute structure, with an alloy cutting blade. The structure is novel and unique, with excellent non-clogging performance, high flow rate, and high wear resistance. A double-end face mechanical seal and a lip seal are used between the pump and the motor. The mechanical seal acts as a dynamic seal, and each fixed stop seal uses a "0"-type oil-resistant rubber seal ring as a static seal to ensure the reliable sealing of the pump. The pump shaft is subjected to high-frequency quenching treatment to ensure reliable mechanical strength, improve wear resistance, and corrosion resistance. The pump inlet is equipped with a cutting disc, and the impeller rotates at high speed. The cutting disc is fixed to the pump body and does not move. During operation, it can cut and tear long fibers, paper towels, and other debris in the water.

Features

● Uses a high-hardness alloy steel spiral impeller, highly wear-resistant, anti-clogging, and anti-winding;

● Equipped with a cutting device that effectively shreds cuttable debris that enters the pump;

● Built-in thermal protector in the motor: prevents motor burnout during abnormal operation such as overload or jamming;

● Motor uses Class B insulation;

Applications

This series of electric pumps are widely used in sewage discharge in municipal sewage treatment, construction projects, hotels, mines, industries, and municipal environmental protection. It is an ideal equipment for pumping mud, slurry, domestic wastewater, sewage, and urine containing short fibers, paper scraps, sand, and other fixed particles, as well as rural irrigation and drainage, and pond dredging.

Operating Conditions

● Medium temperature does not exceed +40°C;

● Medium PH value is 4-10;

● Solid particle content in the medium does not exceed 3%;

● Maximum submersion depth of the pump does not exceed 5m;

● Conveyed medium density ≤1.3x103kg/m 3;

● Power frequency is 50Hz, voltage is single-phase AC 220V, three-phase AC 380V, and voltage fluctuation range is ±10% of the rated value.

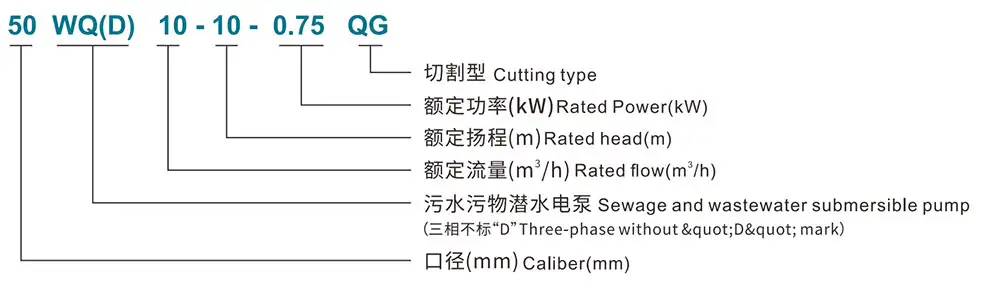

Model Meaning

Technical Parameters

Model Specification |

Rated Flow |

Rated Head |

Maximum Flow |

Maximum Head |

Rated Power |

Synchronous Speed |

Rated Voltage |

Rated Current |

Pipe Inner Diameter |

Head Application Range |

Net Weight |

50WQ(D)10-10-0.75QG |

10 |

10 |

20 |

14 |

0.75 |

3000 |

220/380 |

5.1/2.0 |

51 |

Full Head |

18.2 |

50WQ(D)10-12-1.1QG |

10 |

12 |

25 |

15.5 |

1.1 |

3000 |

220/380 |

7.3/2.7 |

51 |

Full Head |

20.25 |

50WQ(D)15-15-1.5QG |

15 |

15 |

33 |

21 |

1.5 |

3000 |

220/380 |

9.5/3.6 |

51 |

Full Head |

21.7 |

65WQ(D)20-10-1.5QG |

20 |

10 |

33 |

20 |

1.5 |

3000 |

220/380 |

9.5/3.6 |

64 |

Full Head |

21.8 |

50WQ15-20-2.2QG |

15 |

20 |

35 |

24 |

2.2 |

3000 |

380 |

5.1 |

51 |

>15m |

31.8 |

65WQ25-15-2.2QG |

25 |

15 |

35 |

22 |

2.2 |

3000 |

380 |

5.1 |

64 |

Full Head |

32.2 |

80WQ40-10-2.2QG |

40 |

10 |

60 |

18 |

2.2 |

3000 |

380 |

5.1 |

76 |

Full Head |

34 |

50WQ15-25-3QG |

15 |

25 |

45 |

30 |

3 |

3000 |

380 |

6.7 |

51 |

>20m |

/ |

65WQ35-15-3QG |

35 |

15 |

45 |

28 |

3 |

3000 |

380 |

6.7 |

64 |

Full Head |

/ |

80WQ40-15-3QG |

40 |

15 |

62 |

26 |

3 |

3000 |

380 |

6.7 |

76 |

Full Head |

40.8 |

65WQ40-18-4QG |

40 |

18 |

65 |

28 |

4 |

3000 |

380 |

8.0 |

64 |

Full Head |

/ |

80WQ50-15-4QG |

50 |

15 |

65 |

27 |

4 |

3000 |

380 |

8.0 |

76 |

Full Head |

/ |

100WQ80-8-4QG |

80 |

8 |

90 |

29 |

4 |

3000 |

380 |

8.0 |

102 |

Full Head |

46.8 |

Performance Curve

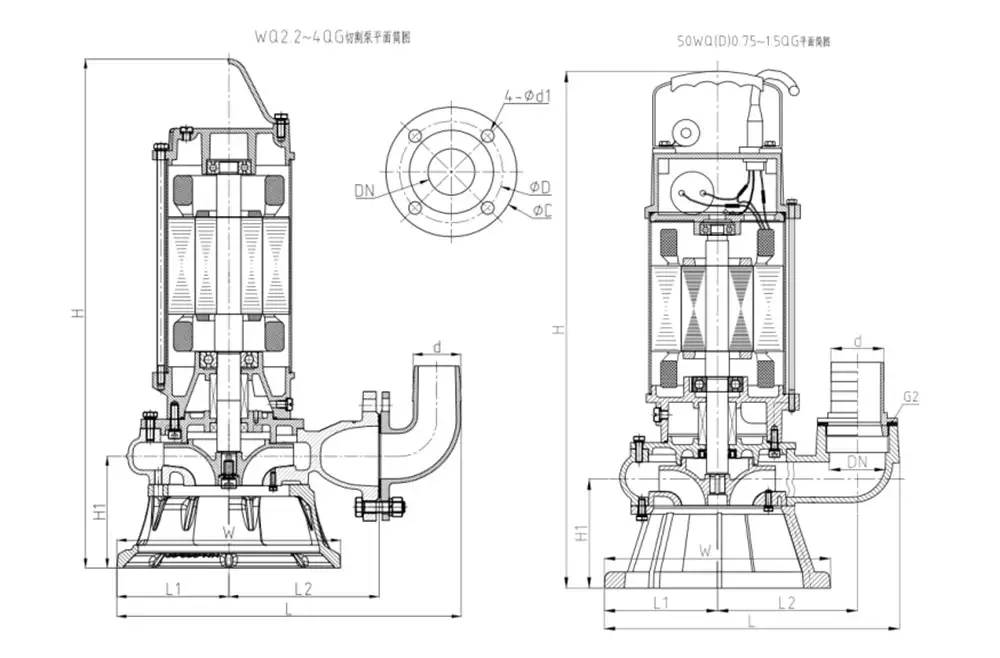

Installation Dimensions

Model Specification |

H |

H1 |

L |

L1 |

L2 |

W |

d |

DN |

D1 |

D |

Flange Thread |

n-¢d1 |

50WQD10-10-0.75QG |

465 |

83 |

267 |

100 |

130 |

200 |

51 |

50 |

/ |

/ |

G2 |

/ |

50WQ10-10-0.75QG |

465 |

83 |

267 |

100 |

130 |

200 |

51 |

50 |

/ |

/ |

G2 |

/ |

50WQD10-12-1.1QG |

484 |

102 |

274 |

105 |

130 |

210 |

51 |

50 |

/ |

/ |

G2 |

/ |

50WQ10-12-1.1QG |

484 |

102 |

274 |

105 |

130 |

210 |

51 |

50 |

/ |

/ |

G2 |

/ |

50WQD15-15-1.5QG |

499 |

104 |

277 |

105 |

130 |

210 |

51 |

50 |

/ |

/ |

G2 |

/ |

50WQ15-15-1.5QG |

499 |

104 |

277 |

105 |

130 |

210 |

51 |

50 |

/ |

/ |

G2 |

/ |

65WQD20-10-1.5QG |

499 |

104 |

277 |

105 |

130 |

210 |

64 |

50 |

/ |

/ |

G2 |

/ |

65WQ20-10-1.5QG |

499 |

104 |

277 |

105 |

130 |

210 |

64 |

50 |

/ |

/ |

G2 |

/ |

50WQ15-20-2.2QG |

550 |

121 |

368 |

120 |

161 |

243 |

51 |

65 |

110 |

140 |

/ |

4-¢14 |

65WQ25-15-2.2QG |

550 |

121 |

380 |

120 |

161 |

243 |

64 |

65 |

110 |

140 |

/ |

4-¢14 |

80WQ40-10-2.2QG |

553 |

124 |

392 |

120 |

160 |

250 |

76 |

80 |

150 |

190 |

/ |

4-¢14 |

50WQ15-25-3QG |

580 |

127 |

363 |

120 |

159 |

240 |

51 |

50 |

110 |

140 |

/ |

4-¢14 |

65WQ35-15-3QG |

580 |

127 |

378 |

120 |

159 |

240 |

64 |

50 |

110 |

140 |

/ |

4-¢14 |

80WQ40-15-3QG |

584 |

127 |

390 |

120 |

160 |

240 |

76 |

80 |

150 |

190 |

/ |

4-¢19 |

65WQ40-18-4QG |

609 |

129 |

397 |

120 |

178 |

240 |

64 |

80 |

150 |

190 |

/ |

4-¢19 |

80WQ50-15-4QG |

609 |

129 |

410 |

120 |

178 |

240 |

76 |

80 |

150 |

190 |

/ |

4-¢19 |

100WQ80-8-4QG |

609 |

129 |

445 |

120 |

178 |

240 |

102 |

100 |

190 |

210 |

/ |

4-¢19 |

Keywords

WQ(D)-QG submersible sewage pump

Contact Us

Classification