Product Overview

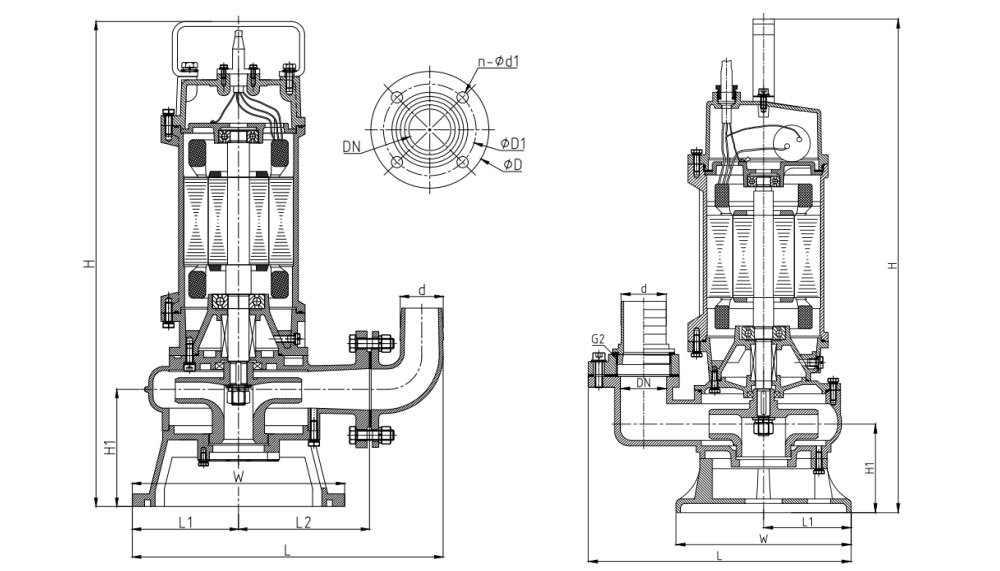

The HWQ(D) series sewage and sludge submersible electric pump (hereinafter referred to as the electric pump) consists of three parts: pump, seal, and motor. The motor is located at the top of the electric pump and is a single-phase or three-phase asynchronous motor. The pump is located below the motor and has a double-flow, non-clogging impeller and volute structure. A double-end face mechanical seal plus a stuffing box oil seal is used between the pump and the motor. The mechanical seal acts as a dynamic seal, and each fixed stop seal uses an oil-resistant rubber "O" ring for static sealing to ensure reliable pump sealing. The pump shaft uses a stainless steel welded shaft to ensure reliable mechanical strength, improve wear and corrosion resistance, and facilitate impeller disassembly and assembly during maintenance. This series of pumps has the characteristics of anti-winding and non-clogging, and has unique functions in conveying mixed liquids containing solid particles and long fibers.

Applications

This series of electric pumps are widely used in: a. Pumping sewage containing solid particles such as short fibers, paper scraps, and sand; b. Pumping sewage containing soft solid substances such as mud, gray water, domestic sewage, and manure; c. Drainage systems of urban sewage treatment plants, municipal engineering, construction sites, agricultural irrigation and drainage, and pond dredging; d. Chemical, petroleum, pharmaceutical, papermaking, and cement plants (not suitable for explosion-proof, strong acid, and strong alkali environments).

Features

● All-copper motor and cold-rolled silicon steel sheet: high efficiency, low temperature rise, not easy to burn out;

● Shaft material high-frequency quenching treatment: improves the wear resistance and corrosion resistance of the shaft, and facilitates impeller maintenance;

● Motor with temperature-type thermal protector: prevents the pump from burning out during abnormal operation such as overload and jamming;

● Mechanical seal structure with stationary ring pressure plate: ensures the sealing of the pump end stationary ring;

● High head, large flow;

● Anti-sand structure design of the impeller: prevents solid particles in the medium from entering the mechanical seal, reducing mechanical seal wear and extending service life.

Operating Conditions

● Medium temperature does not exceed +40℃;

● Medium PH value is 4-10;

● The solid content ratio of solid particles in the medium does not exceed 3%;

● The maximum submergence depth of the water pump does not exceed 5m

● Conveying medium density ≤1.3x10 3 kg/m³;

● Power frequency is 50Hz, voltage is single-phase AC 220V, three-phase AC 380V, and voltage fluctuation range is ±10% of the rated value.

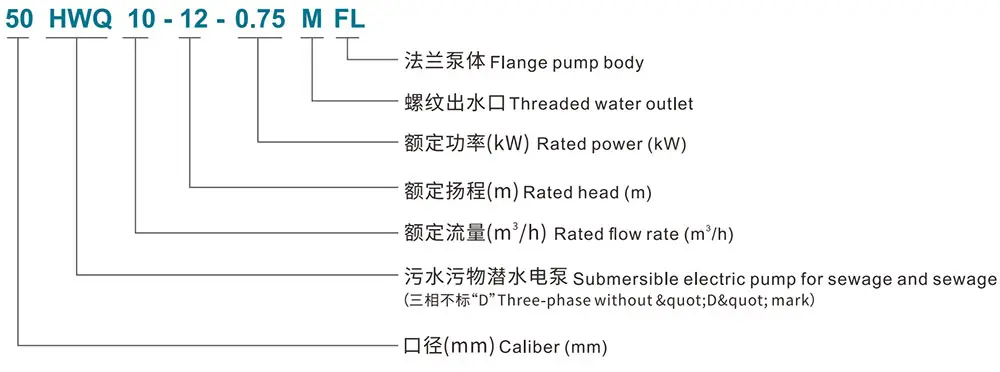

Model Meaning

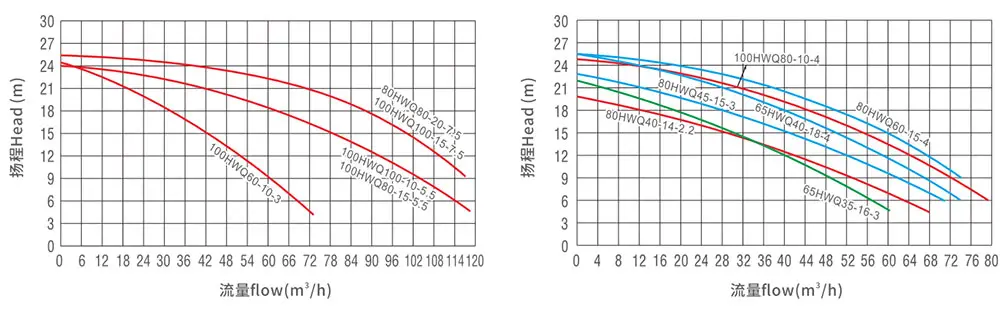

Performance Curve

Technical Parameters

Model Specifications | Rated Flow | Rated Head | Maximum Flow | Maximum Head | Rated Power |

| Rated Voltage | Rated Current | Pipe Inner Diameter | Head Application Range | Maximum Diameter of Particles Passing Through | Net Weight |

40WQ(D)7-15-0.75M | 7 | 15 | 20 | 17 | 0.75 | 3000 | 220/380 | 5.2/2.0 | 40 | >10 | 15 | 21.5 |

50WQ(D)10-12-0.75M | 10 | 12 | 20 | 17 | 0.75 | 3000 | 220/380 | 5.2/2.0 | 51 | Full Head | 15 | 21.5 |

50WQ(D)15-7-0.75M | 15 | 7 | 20 | 17 | 0.75 | 3000 | 220/380 | 5.2/2.0 | 51 | Full Head | 15 | 21.5 |

40WQ(D)7-15-0.75M (Old Model) | 7 | 15 | 20 | 17 | 0.75 | 3000 | 220/380 | 5.2/2.0 | 40 | Full Head | 20 | 22 |

50WQ(D)10-12-0.75M (Old Model) | 10 | 12 | 20 | 17 | 0.75 | 3000 | 220/380 | 5.2/2.0 | 51 | Full Head | 20 | 22 |

50WQ(D)15-7-0.75M (Old Model) | 15 | 7 | 20 | 17 | 0.75 | 3000 | 220/380 | 5.2/2.0 | 51 | Full Head | 20 | 22 |

40WQ(D)7-18-1.1M | 7 | 18 | 30 | 20 | 1.1 | 3000 | 220/380 | 7.3/2.7 | 40 | >12 | 20 | 25.4 |

50WQ(D)10-15-1.1M | 10 | 15 | 30 | 18 | 1.1 | 3000 | 220/380 | 7.3/2.7 | 51 | Full Head | 20 | 25.4 |

50WQ(D)20-10-1.1M | 20 | 10 | 30 | 18 | 1.1 | 3000 | 220/380 | 7.3/2.7 | 51 | Full Head | 20 | 25.4 |

50WQ(D)18-15-1.5M | 18 | 15 | 35 | 20 | 1.5 | 3000 | 220/380 | 9.5/3.6 | 51 | Full Head | 20 | 26.2/25.4 |

50WQ(D)25-10-1.5M | 25 | 10 | 35 | 20 | 1.5 | 3000 | 220/380 | 9.5/3.6 | 51 | Full Head | 20 | 26.2/25.4 |

50WQ(D)10-15-1.1M (FL) | 10 | 15 | 30 | 18 | 1.1 | 3000 | 220/380 | 7.3/2.7 | 51 | Full Head | 20 | 26.05 |

50WQ(D)20-10-1.1M (FL) | 20 | 10 | 30 | 18 | 1.1 | 3000 | 220/380 | 7.3/2.7 | 51 | Full Head | 20 | 26.05 |

50WQ(D)18-15-1.5M (FL) | 18 | 15 | 35 | 20 | 1.5 | 3000 | 220/380 | 9.5/3.6 | 51 | Full Head | 20 | 26.8/26 |

50WQ(D)25-10-1.5M (FL) | 25 | 10 | 35 | 20 | 1.5 | 3000 | 220/380 | 9.5/3.6 | 51 | Full Head | 20 | 26.8/26 |

50HWQ15-20-2.2 | 15 | 20 | 34 | 25 | 2.2 | 3000 | 380 | 5.1 | 51 | Full Head | 20 | 38.6 |

65HWQ35-11-2.2 | 35 | 11 | 52 | 17 | 2.2 | 3000 | 380 | 5.1 | 64 | Full Head | 25 | 37.6 |

80HWQ40-14-2.2 | 40 | 14 | 68 | 21 | 2.2 | 3000 | 380 | 5.1 | 76 | Full Head | 30 | 41.8 |

50HWQ20-25-3 | 20 | 25 | 46 | 30 | 3 | 3000 | 380 | 6.7 | 51 | >20 | 20 | 41.5 |

65HWQ35-16-3 | 35 | 16 | 60 | 23 | 3 | 3000 | 380 | 6.7 | 64 | Full Head | 25 | 40.6 |

80HWQ45-15-3 | 45 | 15 | 70 | 23 | 3 | 3000 | 380 | 6.7 | 76 | Full Head | 30 | 43.5 |

100HWQ60-10-3 | 60 | 10 | 75 | 25 | 3 | 3000 | 380 | 6.7 | 102 | Full Head | 30 | 45.5 |

50HWQ25-30-4 | 25 | 30 | 51 | 35 | 4 | 3000 | 380 | 8.0 | 51 | >20 | 25 | 56 |

65HWQ40-18-4 | 40 | 18 | 75 | 28 | 4 | 3000 | 380 | 8.0 | 64 | Full Head | 25 | 62 |

80HWQ60-15-4 | 60 | 15 | 75 | 28 | 4 | 3000 | 380 | 8.0 | 76 | Full Head | 30 | 62 |

100HWQ80-10-4 | 80 | 10 | 90 | 28 | 4 | 3000 | 380 | 8.0 | 102 | Full Head | 30 | 64 |

80HWQ45-20-5.5 | 45 | 20 | 72 | 28 | 5.5 | 3000 | 380 | 11.7 | 76 | Full Head | 30 | 65 |

100HWQ80-15-5.5 | 80 | 15 | 120 | 20 | 5.5 | 3000 | 380 | 11.7 | 102 | Full Head | 30 | 65 |

100HWQ100-10-5.5 | 100 | 10 | 120 | 20 | 5.5 | 3000 | 380 | 11.7 | 102 | Full Head | 35 | 66 |

150HWQ150-7-5.5 | 150 | 7 | 200 | 18 | 5.5 | 3000 | 380 | 11.7 | 153 | Full Head | 45 | 76 |

80HWQ60-22-7.5 | 60 | 22 | 120 | 27 | 7.5 | 3000 | 380 | 14.5 | 76 | Full Head | 30 | 88 |

100HWQ80-20-7.5 | 80 | 20 | 120 | 27 | 7.5 | 3000 | 380 | 14.5 | 102 | Full Head | 30 | 89 |

100HWQ100-15-7.5 | 100 | 15 | 120 | 27 | 7.5 | 3000 | 380 | 14.5 | 102 | Full Head | 35 | 89 |

150HWQ150-12-7.5 | 150 | 12 | 230 | 22 | 7.5 | 3000 | 380 | 14.5 | 153 | Full Head | 45 | 105 |

50WQ(D)10-15-0.75TM | 10 | 15 |

|

| 0.75 | 3000 |

|

| 51 | Full Head | / | 16.9 |

50WQ(D)10-15-1.1TM | 10 | 15 |

|

| 1.1 | 3000 | 220/380 | 7.3/2.7 | 51 | Full Head | / | 17.35 |

50WQ(D)12-16-1.5TM | 12 | 16 | / | / | 1.5 | 3000 | 220/380 | 9.5/3.6 | 51 | Full Head | / | 21.1 |

80WQ(D)40-9-1.5TM | 40 | 9 | / | / | 1.5 | 3000 | 220/380 | 9.5/3.6 | 76 | Full Head | / | 22.9 |

100WQ(D)65-7-2.2TM | 65 | 7 | / | / | 2.2 | 3000 | 220/380 | 14/5.1 | 102 | Full Head | / | 26.15 |

100WQ(D)65-10-3TM | 65 | 10 | / | / | 3 | 3000 | 220/380 | 17/6.7 | 102 | Full Head | / |

|

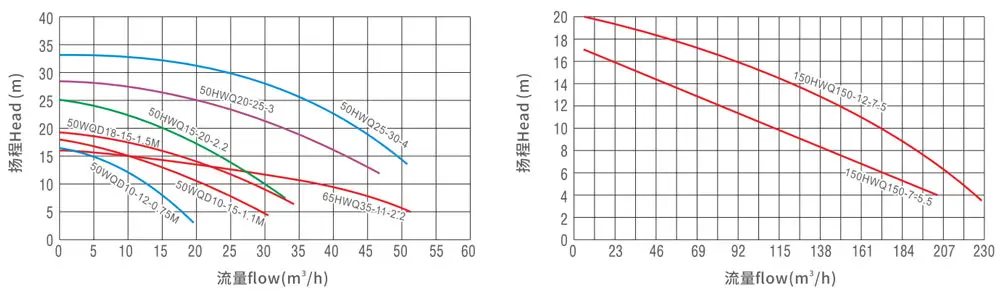

Installation dimensions

| Model specifications | H | H1 | L | L1 | L2 | W | d | DN | D1 | D | Flange thread | d n-¢d1 |

| 50WQD10-12-0.75M | 478 | 73 | 252 | 95 | / | 190 | 51 | 50 | / | / | G2 | / |

| 50WQ10-12-0.75M | 478 | 73 | 252 | 95 | / | 190 | 51 | 50 | / | / | G2 | / |

| 50W QD10- 12-0 . 75M(old model) | 495 | 88 | 249 | 95 | / | 192 | 51 | 50 | / | / | G2 | / |

| 50WQ10- 12-0 . 75M(old model) | 495 | 88 | 249 | 95 | / | 192 | 51 | 50 | / | / | G2 | / |

| 50WQD10-15-1.1M | 540 | 97 | 263 | 95 | 168 | 190 | 51 | 50 | / | / | G2 | / |

| 50WQ10-15-1.1M | 540 | 97 | 263 | 95 | 168 | 190 | 51 | 50 | / | / | G2 | / |

| 50WQD18-15-1.5M | 540 | 97 | 263 | 95 | 168 | 190 | 51 | 50 | / | / | G2 | / |

| 50WQ18-15-1.5M | 540 | 97 | 263 | 95 | 168 | 190 | 51 | 50 | / | / | G2 | / |

| 50WQD10-15-1.1FL | 540 | 97 | 263 | 95 | 130 | 190 | 51 | 50 | 110 | 140 | / | 4-¢14 |

| 50WQ10-15-1.1FL | 540 | 97 | 263 | 95 | 130 | 190 | 51 | 50 | 110 | 140 | / | 4-¢14 |

| 50WQD18-15-1.5FL | 540 | 97 | 263 | 95 | 130 | 190 | 51 | 50 | 110 | 140 | / | 4-¢14 |

| 50WQ18-15-1.5FL | 540 | 97 | 263 | 95 | 130 | 190 | 51 | 50 | 110 | 140 | / | 4-¢14 |

| 50HWQ15-20-2.2 | 582 | 140 | 370 | 126 | 157 | 252 | 51 | 50 | 110 | 140 | / | 4-¢14 |

| 65HWQ35-11-2.2 | 572 | 131 | 390 | 126 | 165 | 252 | 64 | 65 | 130 | 160 | / | 4-¢14 |

| 80HWQ40-14-2.2 | 576 | 134 | 409 | 126 | 170 | 252 | 76 | 80 | 150 | 190 | / | 4-¢19 |

| 50HWQ20-25-3 | 602 | 140 | 370 | 126 | 157 | 252 | 51 | 50 | 110 | 140 | / | 4-¢14 |

| 65HWQ35-16-3 | 592 | 131 | 390 | 126 | 165 | 252 | 64 | 65 | 130 | 160 | / | 4-¢14 |

| 80HWQ45-15-3 | 596 | 134 | 409 | 126 | 170 | 252 | 76 | 80 | 150 | 190 | / | 4-¢19 |

| 100HWQ60-10-3 | 604 | 140 | 459 | 126 | 186 | 260 | 102 | 100 | 170 | 210 | / | 4-¢19 |

| 50HWQ25-30-4 | 648 | 140 | 370 | 126 | 157 | 252 | 51 | 50 | 110 | 140 | / | 4-¢14 |

| 65HWQ40-18-4 | 642 | 134 | 395 | 126 | 170 | 252 | 64 | 80 | 150 | 190 | / | 4-¢19 |

| 80HWQ60-15-4 | 642 | 134 | 409 | 126 | 170 | 252 | 76 | 80 | 150 | 190 | / | 4-¢19 |

| 100HWQ80-10-4 | 650 | 140 | 459 | 126 | 186 | 260 | 102 | 100 | 170 | 210 | / | 4-¢19 |

| 80HWQ45-20-5.5 | 722 | 159 | 445 | 131 | 201 | 277 | 76 | 100 | 170 | 210 | / | 4-¢19 |

| 100HWQ80-15-5.5 | 722 | 159 | 478 | 131 | 201 | 277 | 102 | 100 | 170 | 210 | / | 4-¢19 |

| 100HWQ100-10-5.5 | 722 | 159 | 478 | 131 | 201 | 277 | 102 | 100 | 170 | 210 | / | 4-¢19 |

| 150HWQ150-7-5.5 | 766 | 211 | 614 | 185 | 230 | 370 | 152 | 150 | 225 | 265 | / | 8-¢19 |

| 80HWQ60-22-7.5 | 752 | 159 | 445 | 131 | 201 | 277 | 76 | 100 | 170 | 210 | / | 4-¢19 |

| 100HWQ80-20-7.5 | 752 | 159 | 478 | 131 | 201 | 277 | 102 | 100 | 170 | 210 | / | 4-¢19 |

| 100HWQ100-15-7.5 | 752 | 159 | 478 | 131 | 201 | 277 | 102 | 100 | 170 | 210 | / | 4-¢19 |

| 150HWQ150-12-7.5 | 822 | 211 | 614 | 185 | 230 | 370 | 152 | 150 | 225 | 265 | / | 8-¢19 |

Keywords

HWQ(D) submersible sewage pump

Contact Us

Classification

Related Products

There is no relevant data for the time being, please add it backstage!