|

|

U-shaped impeller Vortex impeller, which can generate vortex flow and extract thicker sludge or liquids containing long fibers. |

P-shaped impeller Open impeller, which can be divided into single-blade or double-blade impellers. The blades can cut off general foreign objects, preventing solid waste from blocking and reducing the occurrence of pump blockage failures. |

Product Overview

The F-series non-clogging sewage submersible pump (hereinafter referred to as the pump) consists of three parts: a water pump, a seal, and a motor. The motor is located at the top of the pump and is a single-phase or three-phase asynchronous motor. The water pump is located below the motor and has a semi-open vortex impeller and volute structure. A double-end face mechanical seal plus a stuffing box oil seal is used between the water pump and the motor. The mechanical seal acts as a dynamic seal, and each fixed stop seal uses a "0"-type oil-resistant rubber seal ring as a static seal. The entire pump uses stainless steel bolts, and the pump casing is treated with electrophoresis and spray painting, effectively isolating air and water, preventing oxidation, and extending service life. The pump has an external current-type protector, F-class insulation grade, and the cable is waterproofed to prevent the pump from burning out.

Features

● Uses a non-blocking impeller design: It can exert maximum drainage function for sewage containing solids or fibrous materials;

● High-precision motor, high efficiency, the rotating shaft is processed by heat treatment, and the characteristics are stable;

● Motor with external current-type thermal protector: Prevents the water pump from burning out during abnormal operation such as overload and jamming;

● The motor uses a new sealing structure, which has good sealing performance and ensures that it will not be damaged during assembly;

● Single-phase motors are equipped with a mechanical centrifugal switch design: Solves the problem of difficulty starting the motor due to low voltage;

● All series cables use rubber cables with waterproof treatment: Prevents water vapor from entering the motor through the cables, avoiding motor dampness and water ingress;

● All cast iron parts use standard grade gray cast iron 200.

Applications

● Domestic sewage discharge;

● Rainwater accumulation discharge;

● Wastewater treatment in industries such as food, leather, pulp, steel, and electronics;

● Wastewater treatment in livestock and pig farms.

Operating Conditions

● The pump frequency is 50Hz, and the voltage is 220V single-phase AC and 380V three-phase AC;

● The voltage fluctuation range is ±10% of the rated value;

● Operating ambient temperature 0~40°C, conveying medium temperature does not exceed +40°C;

● Conveying medium viscosity ≤1.3x10 3kg/m3;

● The solid content ratio of solid particles in the medium does not exceed 3%;

● Submersion depth does not exceed 5m;

● The PH value of the conveying medium is between 4-10.

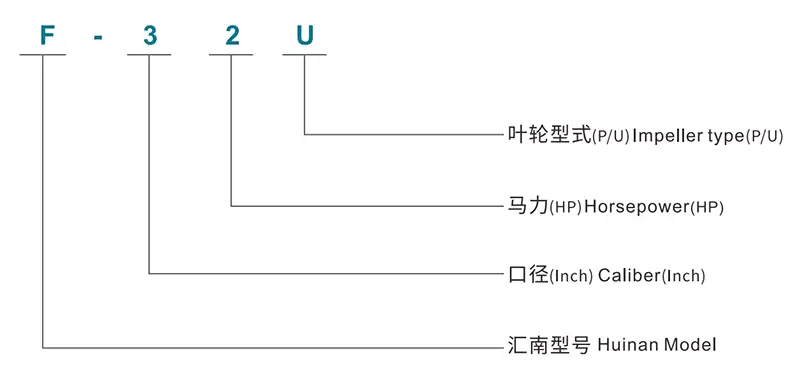

Model Meaning

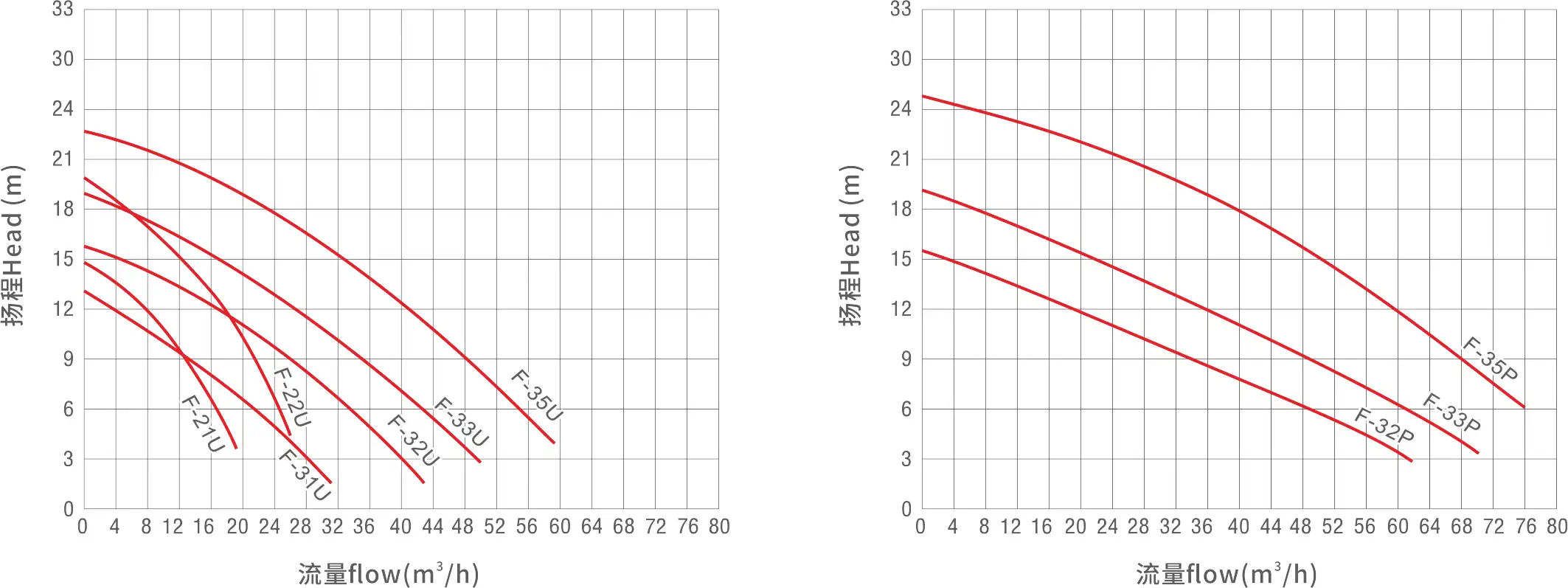

Performance Curve

Technical Parameters

Model Specifications |

Rated Flow |

Rated Head |

Maximum Flow |

Maximum Head |

Rated Power |

Synchronous Speed |

Rated Voltage V |

Rated Current |

Pipe Inner Diameter mm |

Pump External Dimensions |

Passing Particles |

F-21U |

12 |

9.5 |

19 |

15 |

0.75 |

3000 |

220/380 |

7.3/2.7 |

50 |

238×154×458 |

35 |

F-31U |

18 |

7.5 |

32 |

13 |

0.75 |

3000 |

220/380 |

7.3/2.7 |

80 |

275x174x460 |

30 |

F-22U |

12 |

15 |

26 |

20 |

1.5 |

3000 |

220 |

9.5 |

50 |

290x205x568 |

35 |

F-22U |

12 |

15 |

26 |

20 |

1.5 |

3000 |

380 |

3.6 |

50 |

290x205x478 |

35 |

F-32U |

25 |

9 |

42 |

16 |

1.5 |

3000 |

220 |

9.5 |

80 |

262x205x610 |

50 |

F-32U |

25 |

9 |

42 |

16 |

1.5 |

3000 |

380 |

3.6 |

80 |

262x205x520 |

50 |

F-33U |

25 |

12.5 |

50 |

19 |

2.2 |

3000 |

220 |

14 |

80 |

262x205x640 |

50 |

F-33U |

25 |

12.5 |

50 |

19 |

2.2 |

3000 |

380 |

5.1 |

80 |

262x205x540 |

50 |

F-35U |

30 |

16.5 |

59 |

23 |

3.7 |

3000 |

380 |

7.4 |

80 |

262x205x570 |

50 |

F-32P |

36 |

8.5 |

58 |

15.5 |

1.5 |

3000 |

220 |

9.5 |

80 |

275x260x612 |

35 |

F-32P |

36 |

8.5 |

58 |

15.5 |

1.5 |

3000 |

380 |

3.6 |

80 |

275x260x522 |

35 |

F-33P |

36 |

12.5 |

65 |

19 |

2.2 |

3000 |

220 |

14 |

80 |

275x260x642 |

35 |

F-33P |

36 |

12.5 |

65 |

19 |

2.2 |

3000 |

380 |

5.1 |

80 |

275x260x542 |

35 |

F-35P |

36 |

19 |

76 |

27 |

3.7 |

3000 |

380 |

7.4 |

80 |

275x260x572 |

35 |

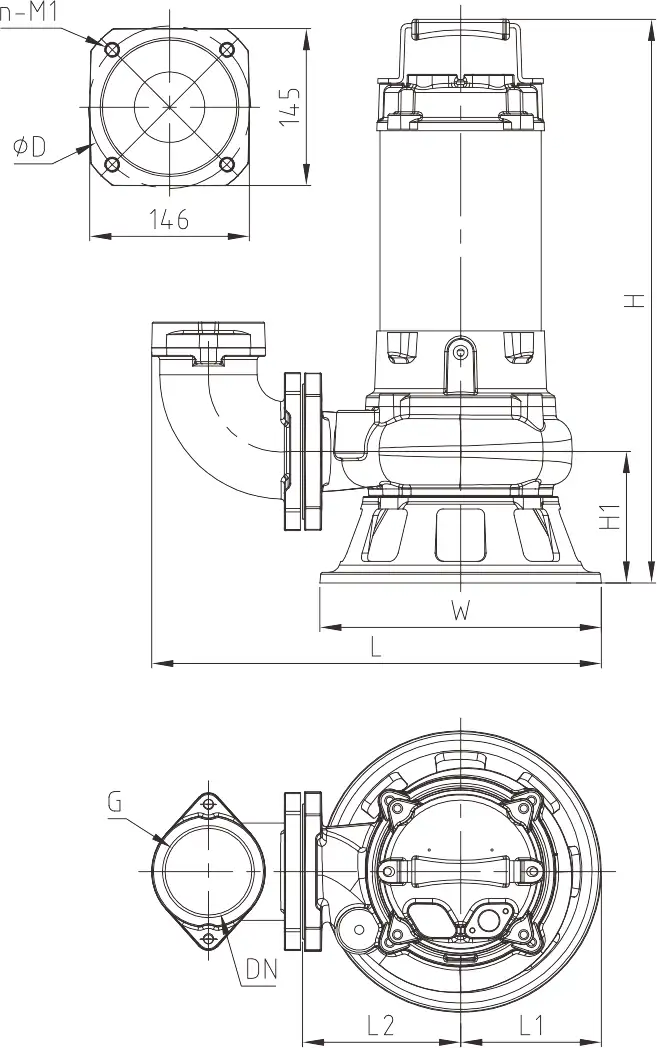

Installation Dimensions

Model Specifications |

H |

H1 |

L |

L1 |

L2 |

W |

DN |

D |

G |

n-M1 |

|

F-21U |

458 |

64 |

238 |

85 |

153 |

154 |

φ50 |

/ |

G2 |

/ |

|

F-31U |

460 |

73 |

275 |

87 |

188 |

174 |

φ80 |

/ |

G3 |

/ |

|

F-22U(220V/50Hz) |

568 |

60 |

290 |

116 |

175 |

205 |

φ50 |

/ |

G2 |

/ |

|

F-22U(380V/50Hz) |

478 |

60 |

290 |

116 |

175 |

205 |

φ50 |

/ |

G2 |

/ |

|

F-32U(220V/50Hz) |

610 |

82 |

402 |

116 |

147 |

205 |

φ80 |

φ150 |

G3 |

4-M14 |

|

F-32U(380V/50Hz) |

520 |

82 |

402 |

116 |

147 |

205 |

φ80 |

φ150 |

G3 |

4-M14 |

|

F-33U(220V/50Hz) |

640 |

82 |

402 |

116 |

147 |

205 |

φ80 |

φ150 |

G3 |

4-M14 |

|

F-33U(380V/50Hz) |

540 |

82 |

402 |

116 |

147 |

205 |

φ80 |

φ150 |

G3 |

4-M14 |

|

F-35U(380V/50Hz) |

570 |

82 |

402 |

116 |

147 |

205 |

φ80 |

φ150 |

G3 |

4-M14 |

|

F-32P(220V/50Hz) |

612 |

122 |

415 |

130 |

145 |

260 |

φ80 |

φ150 |

G3 |

4-M14 |

|

F-32P(380V/50Hz) |

522 |

122 |

415 |

130 |

145 |

260 |

φ80 |

φ150 |

G3 |

4-M14 |

|

F-33P(220V/50Hz) |

642 |

122 |

415 |

130 |

145 |

260 |

φ80 |

φ150 |

G3 |

4-M14 |

|

F-33P(380V/50Hz) |

542 |

122 |

415 |

130 |

145 |

260 |

φ80 |

φ150 |

G3 |

4-M14 |

|

F-35P(380V/50Hz) |

572 |

122 |

415 |

130 |

145 |

260 |

φ80 |

φ150 |

G3 |

4-M14 |

Keywords

F-series non-clogging sewage submersible pump

Contact Us

Classification

Related Products

There is no relevant data for the time being, please add it backstage!